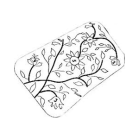

Since time immemorial, the art of carpet making has captured millions of carpet connoisseurs from around the world and still continues to do so. Behind each carpet is an extraordinary story that is depicted beautifully in these pieces of art. Such handcrafted timeless collectibles are passed on to generations as memorabilia and preserved in its truest form.

Artistically and characteristically, Kashmir silk carpets with Persian designs are the most superior amongst different types of carpets. Various hues of colors, innate designs, and intricate patterns form the most essential part of such carpets. Silk carpets have a unique luster and shine to its touch and feel and the color of the carpet is changed with its direction due to its pile and weaving technique.

They say beauty lies in the eyes of the beholder. This adage is true in the case of handmade Persian design carpets which are perfect examples of Chef d'oeuvres (masterpieces). Most handmade carpets come with fringes/tassels which only enhance the beauty of a rug. Each handmade carpet takes about 9-12 months on an average to make with about 2-3 people working on it. Beauty is of the essence and there are thousands of weavers in the villages whose livelihood depends on making such carpets. It is essential to appreciate these handmade carpets that are of extraordinary brilliance.

Other than pure silk carpets, blended wool and silk carpets have also gained much popularity. Such carpets are an amalgamation of blended New Zealand wool and Fine silk. These inherently beautiful rugs are a result of great craftsmanship that is rare to find in any part of the world.

Wool is known to be one of the strongest fibers due to its tenacity and strength. Woolen carpets are a combination of New Zealand and Indian wool which are used in constructing Persian design rugs as well. Such carpets form a primordial part of Eastern Europe and India as well and date back to a couple of centuries altogether. Woolen carpets are perfect for traffic areas and have excellent durability.

Runners are long and usually narrow and ideal for corridors, staircases and passageways. While round carpets are ideal for foyers and areas of importance. Over a period of time, the newer generation has found interest in lesser laborious jobs and have moved into other industries. It is for this reason; exclusive carpet making is becoming rare whereas the demand has just been escalating like never before. Rugs and Beyond strives to keep the art of carpet making alive by means of supporting its talented weavers and local weavers who are Masters of weaving beautiful rugs and carpets, by hand.

Most of the people think that how to make an intricate design in best quality handmade carpet or what dying process to be used for color fixing, about materials and most of the important that what is the process of weaving handmade carpets. So I am going to describe here that what is the actual process has done for making handmade carpets.

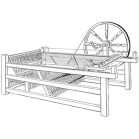

Turning material into yarns: This is the starting process or we can say the first process of weaving handmade carpet. When material arrives in a factory in the large bale, weavers use a hand machine which is called chakra for finishing and making yarn bundles.

Washing: This is the second step. This process is important because when unprocessed materials come, those are dirty, contains dust and grease. So in the washing process, these are removed. Yarns are simply washed by detergent and it is then sun-dried for two or three days.

Dying Process: This is a very important process because all looks of carpets are depended on yarn color. For handmade carpets they are using vegetable dye, Chemical dye. Vegetable dyeing process mostly uses to give indigo colors. Vegetable dye is not 100% fast. It means when you will wash the carpet, it will fade a bit. But the chemical dying process mostly used for fixing the colors. The yarn is hung onto a vertical pole and submerges into the dye. The dye is heated to the boiling temperature for a limited time. The time depends on the color combination such as for the dark color it takes more time as compare to light colors.

Hand knotted carpets: Before weaving the design artist has drawn the designs on graph paper. After that, they make foundation which is called hand loom. The columns of threads are called warp which is vertically stitched on the loom. Warp is mostly in cotton. The weavers make designs which are called weft. The weft is of wool, silk, cotton, chenille etc. After creating about ten wefts the weavers work fast. Using a piece of wool or silk, they take one or two warp in the same row and tie knots around them. The ends of knots called piles. Weavers work knots by knots until the pattern is complete. This is the most intricate weaving process. These carpets have very high durability due to knots and weaving technique. Hand-knotted carpets are very exclusive and also expensive as compare to all rug.

Hand Tufted Carpets: This type of carpet also called as cut pile carpets. The rug pattern is drawing on the primary backing of cloth. After that, the cloth is stitched on the frame. Then the craftsmen insert the material such as wool, silk or other into the primary cloth using the single needle tools (gun). When the tufting is completed then they cover primary backing with a hard material. The secondary backing is added for protecting the primary backing. After that, they bind the edges of the rugs to add strengths.

Trimming or finishings: When the weaving process has been done after that the carpets are trimming by scissor.

Washing Carpets: After trimming process, the carpet is washed with cold fresh water and dried in shadows. This is very important for carpet care.

Final Touches: This is the last step when the rugs are ready they gave final touch by re-finishing and stretching, where it is necessary.